PREMIUM EGG PRODUCTS

Farm Fresh Grade-A White Eggs, 55–60g, Haugh Unit >72

Graded, UV-Cleaned, Retail Ready Packs (6, 10, 12, 30 eggs)

Bulk Supplies to Institutional Buyers, Hotels, and Retail Chains

30-egg trays (recycled pulp), Retail, Hotels, Government Supplies & Export

Organic Brown Eggs, 50–53g

12-egg cardboard boxes for E-grocery platforms

Salmonella-free (lab-tested monthly)

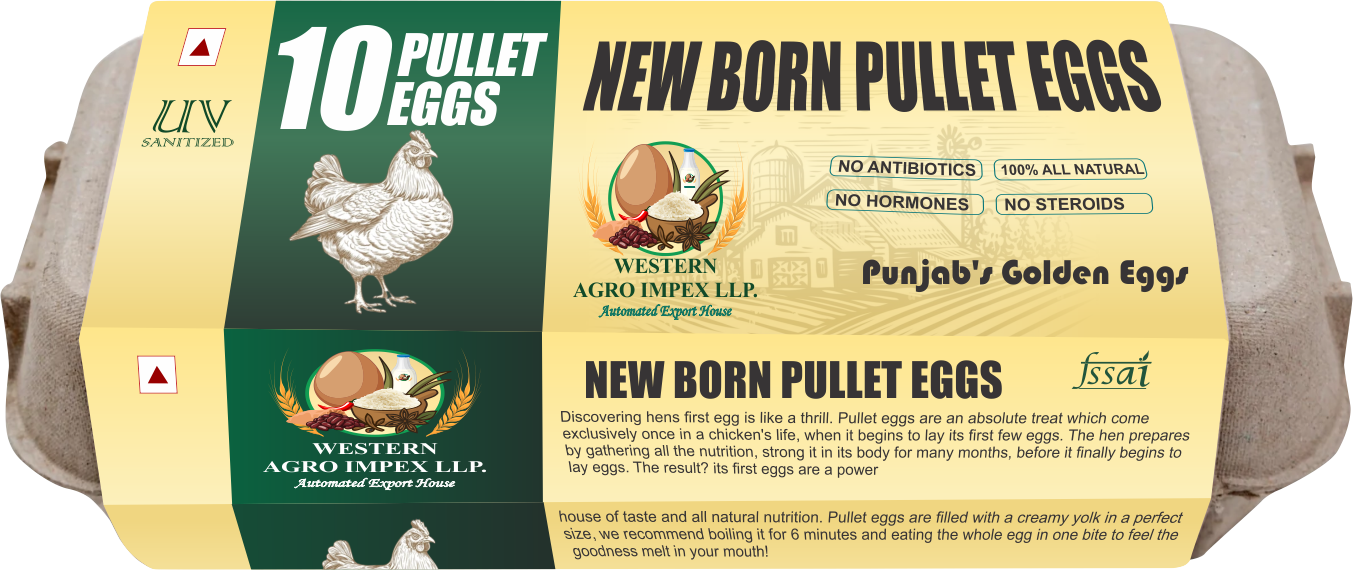

UV Sanitized Eggs

What Makes Our Eggs Exceptional?

Internationally Compliant

Complies fully with EU, USDA, & GCC food safety standards.

Advanced Grading

Automated grading ensures precise size and weight sorting for uniformity.

Strict Quality Control

Rigorous quality control certified under HACCP and ISO 22000 standards.

Traceability

Batch tracking guarantees freshness and quality assurance.

Sustainable Packaging

Eco-friendly, robust, and optimized for international shipping.

FSSAI Approved

Fully compliant with India’s premier food safety regulations.

Our Egg Grading Process

Collection & Pre-Cleaning

Fresh eggs from trusted and certified farms.

Candling & Inspection

Optical scanning to detect and remove cracked or defective eggs.

Weight & Size Grading

Precision sorting (S, M, L, XL, Jumbo).

Washing & Sanitizing

Food-grade disinfectants ensure safety.

Drying & Oiling

Protective coating applied to enhance shelf life.

Stamping & Labelling

Includes farm details, expiry date, and certifications.

Automated Packaging

Customized trays or cartons for local and export markets.

UV Sanitization Tunnel

Kills 99.9% of pathogens for ultimate hygiene.

INLINE EGG PROCESSING UNIT

Grading

Technology: Computer vision + weight sensors

Capacity: 108,000 eggs/hour

Stamping

Technology: Laser date-coding (FSSAI compliant)

Capacity: 108,000 eggs/hour

Packaging

Technology: Robotic arm loading + auto-sealing

Capacity: 3,600 trays/hour

Ideal For

- Health-conscious consumers

- Hotels, restaurants, and sustainable retailers

- Investors focused on ESG-compliant agri-businesses

- Government partnerships for rural development

Why Automation?

- Zero Human Contact = Higher Food Safety

- 90% Labor Cost Reduction

- 100% Traceability from farm to consumer

- 10× Faster Processing than manual farms

- 99% Egg Hygiene with robotic handling

- One million eggs processed every day

OUR INFRASTRUCTURE

DRY CLEANING

Removes any external impurities from the eggs, maintaining the cleanliness and integrity of the eggshell.

CANDLING

A precise method of illuminating eggs to inspect for quality, ensuring that only eggs meeting stringent standards proceed to the next stages.

UV TREATMENT

Meticulous process that minimizes microbial contamination, guaranteeing the safety of the products.

GRADING

Meticulously grades eggs based on size, weight, and quality, ensuring high quality eggs with each purchase.

EXPIRY DATE

We ensure transparency & consumer safety by imprinting accurate expiry dates on each egg, allowing customers to make informed choices about freshness and consumption.